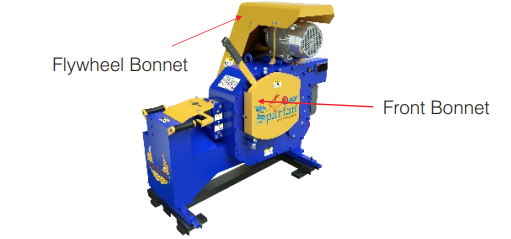

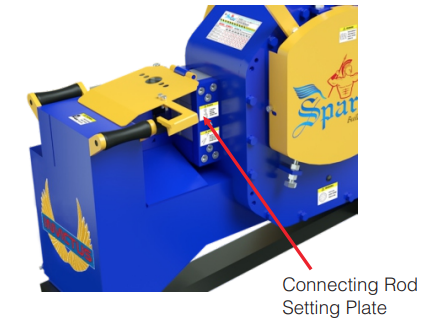

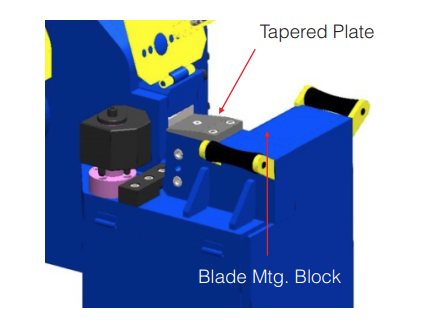

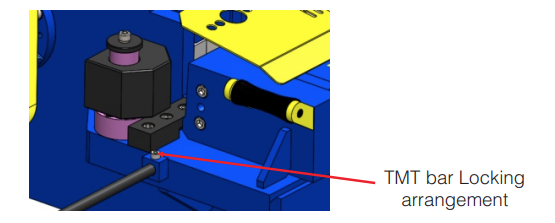

Setting plate design has been upgraded and strengthen

| Model | Machine Dimensions (L x W x H) | Weight | Motor Capacity | Stroke /Min. | Oil Grade & Capacity | Capacity | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| SCM 52V | 1135 X 740 X 930 mm | 546 Kg | 5 HP, 3.7 kW | 60 | OMALO 460, 4.75 ltr | 36 mm upto 78kg/mm^ | |||||

| Features | SCM - 52V | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Dia of Bars (Max. Dia in mm | 40 | 36 | 32 | 25 | 20 | 16 | 12 | 10 | 8 |

| No. of Bars Tensile strength 41- 50 kg/mm^2 | 1 | 1 | 1 | 2 | 2 | 3 | 5 | 6 | 8 |

| No. of Bars Tensile strength 51-60 Kg/mm^2 | 1 | 1 | 1 | 2 | 3 | 4 | 6 | 8 | |

| No. of Bars Tensile strength 61-70 Kg/mm^2 | - | 1 | 1 | 1 | 2 | 3 | 4 | 5 | 7 |

| No. of Bars EQR (Tensile strength 71-78 Kg/mm^2) | - | 1 | 1 | 1 | 2 | 3 | 4 | 5 | 7 |

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

WhatsApp us