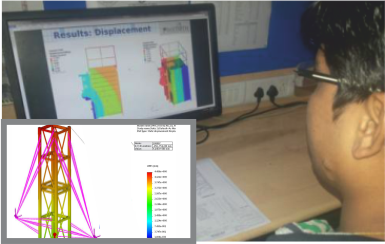

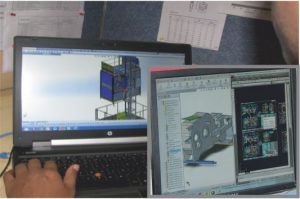

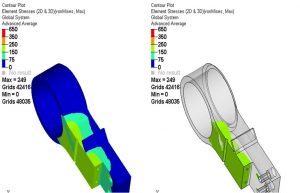

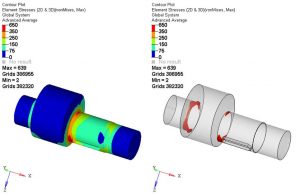

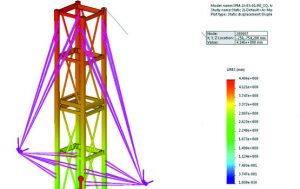

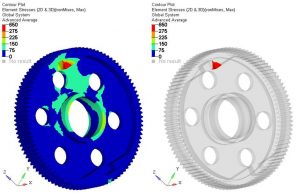

Spartan has been pioneer in designing and developing construction equipment. Spartan boasts of a team of 30 experienced and expert designers. This team is dedicated for designing, engineering and product development activities. It is well equipped with highly configured workstations along with latest and advanced design software like Solidworks and AutoCad. The design engineers study the structural, static & dynamic load requirement, load deflection characteristics & working conditions of the end application. Spartan’s design team designs entire structure on the basis of FE Analysis by considering various loading conditions to ensure the life, reliability and safety thereby confirming the structural stability of the product.

All the machines are deigned as per international standards- CE. The machines are designed electrically as per European EN standards and thus are CE certified. CE certification consists of safety assessment tests, load test to ensure structural strength, FE Analysis reports of all components and electrical safety test- Low/ High Voltage tests.

It includes Emission tests like Radiated Emission- IEC 61000-6-4, Conducted Emission- IEC 61000-6-4, Electrostatic Discharge IEC 61000-6-2 & Electrical Fast Transient- IEC 61000-6-2.

CE testing ensures performance, safety & environmental protection. Machine passes through various assessments International market norms like Structural Strength, Equipment Safety, Operator Safety & Product optimizations. The team follows all the documents controlled as per ISO 90001:2015. This includes Design Review Note, D&D Planning, Design Feasibility Report, Design Verification & Validation, and Design Project Specification Sheet & Design NPD MOM. The design team functions on 3 primary roles, New Product Development, Customised Design Solutions & Pre Order support. It follows problem solving & improvement tolls like Kaizen & 8D RCA. This helps continuous quality improvement, reduce customer complaints and prevention of recurrence. 8D RCA is a 8 step analysis to find the root cause of internal & external complaints. This ensures corrective & preventive actions. Kaizen means change for better. This helps to improve continuously.

Spartan holds NPD (New Product Development) meetings, where each of HOD from various departments like design, production, marketing, customer care, etc. come together to discuss on various successful machines across the globe. These machines are discussed and finalized during NPD meetings and shared with the design team for further development.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

WhatsApp us