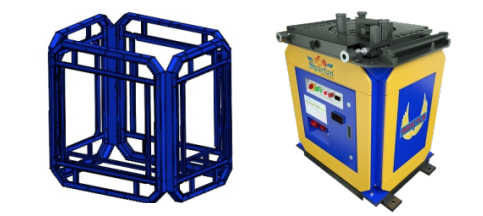

| Model | Machine Dimensions (L x W x H) | Overall Weight | Motor Capacity | Bend Wheel Speed | Bend Wheel Dia Ø | Max. Bend Radius | Bushes Supplied |

|---|---|---|---|---|---|---|---|

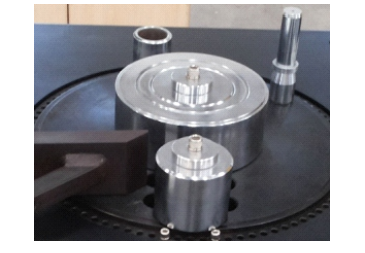

| SBM 55 V | 1060 x 950 x 1235 mm | 555 Kg | 7.5 HP | 6.0 rpm | 500 mm | 6D of Ø36, 5D of Ø40 | Ø60, Ø70, Ø100, Ø120, Ø160 & Ø220 |

| Features | SBM - 55V | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Dia of Bars (Max. Dia in mm | 40 | 36 | 32 | 25 | 20 | 16 | 12 | 10 | 8 |

| No. of Bars Tensile strength 41- 50 kg/mm^2 | 1 | 1 | 1 | 2 | 2 | 3 | 5 | 7 | 8 |

| No. of Bars Tensile strength 51-60 Kg/mm^2 | 1 | 1 | 1 | 2 | 2 | 3 | 5 | 7 | 8 |

| No. of Bars Tensile strength 61-70 Kg/mm^2 | 1 | 1 | 1 | 2 | 2 | 3 | 5 | 6 | 8 |

| No. of Bars EQR (Tensile strength 71-78 Kg/mm^2) | 1 | 1 | 1 | 2 | 2 | 3 | 5 | 6 | 8 |

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

WhatsApp us