| Capacity Chart of SBM 16V | ||||

|---|---|---|---|---|

| Features | Stirrup Bending Machine SBM 16V | |||

| Dia of Bars (Max. Dia in mm) | 12 | 10 | 8 | 6 |

| No. of Bars Tensile strength 41-50 Kg/mm^2 (Elongation - 12% Max) | 1 | 2 | 5 | 6 |

| No. of Bars Tensile strength 51-60 Kg/mm^2 (Elongation - 16% Max) | 1 | 2 | 4 | 6 |

| No. of Bars Tensile strength 61-70 Kg/mm^2 (Elongation - 14.5/10% Max) | - | 1 | 4 | 6 |

| Technical Specifications of SBM 16V | |

|---|---|

| Machine Dimensions (L x W x H) | 1485 x 585 x 825 |

| Overall Weight | 125 Kg |

| Motor Capacity | 1 HP |

| Bend Wheel Speed | 18 rpm |

| Bend Wheel Dia Ø | 125 Kg |

| Spiral Rod Bending Machine | |

|---|---|

| Capacity (mm) | 6-20 |

| Motor Power (HP/KW) | 5 HP / 3.75 kW |

| Bend Wheel Speed | 9.04 RPM |

| Circular Bending Angle | 360 Degree |

| Net Weight in KG | 385 Kgs. |

| Dimensions (LxWxH) | 1075(L) x 895 (W) x 1015 (H) |

| Features | Spiral Rod Bending Machine SSB 52 | |||||

|---|---|---|---|---|---|---|

| Dia of Bars (Max. Dia in mm) | 20 | 16 | 12 | 10 | 8 | 6 |

| Ring Dia Ø Min. (mm) | 800 | 450 | 350 | 300 | 275 | 250 |

| Dia of Bars (Max. Dia in mm) | Upto 3 mtr. | |||||

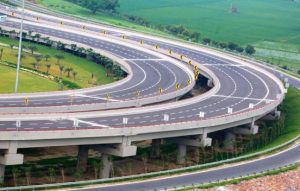

Spartan’s Bar Bending Machines have been the most rugged and accurate bending machines found in India. While Spartan is known for its safety and reliability, the bar bending machines offer you the most efficient performance. It is manufactured in the most advanced state of the art manufacturing facility. The rugged design is suitable to work in every site condition in India. You will find our machines working across all major cities in India and also on variety of infrastructure projects across India.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

WhatsApp us