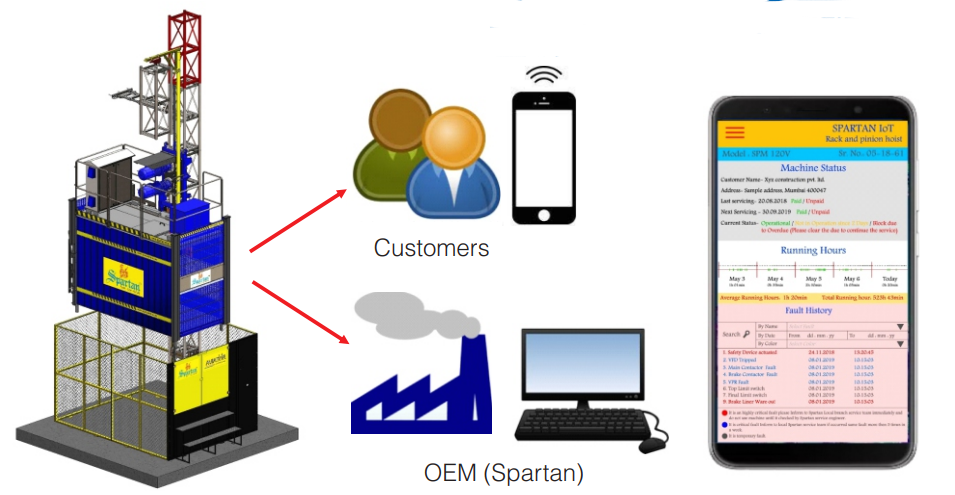

Customer access following data of machine

OEM with following information

| Model | SPM 200-200T | ||

|---|---|---|---|

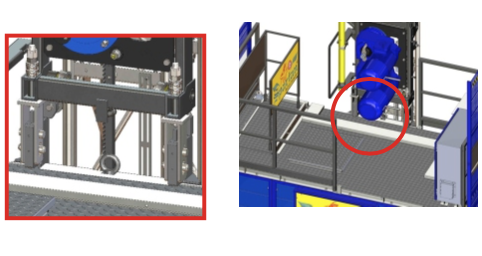

| Drive Mechanism | Rack & Pinion | ||

| Capacity | 2.0 Ton (Each Cage) | ||

| Max Height | 250 mtrs. | ||

| Speed | 30 mtr/ min. | 54 mtr/ min. | ||

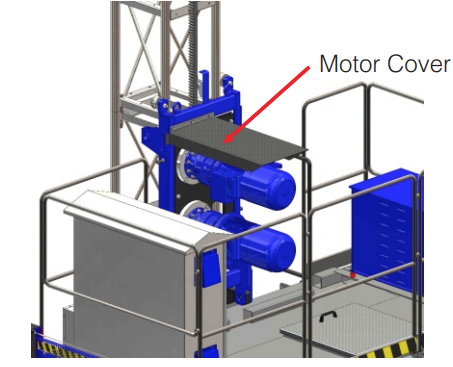

| Motor Power | 11 kW (50Hz) x 2 Nos(Each cage). | 18.5kW (50Hz) x 2 Nos(Each cage) | ||

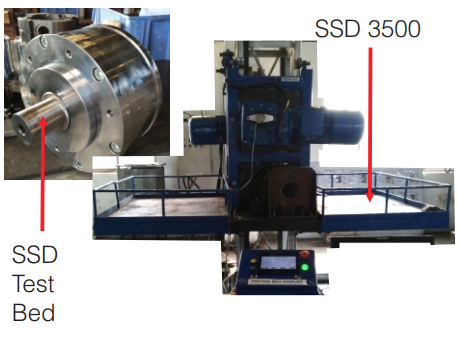

| Safety Device | SSD 3500 | ||

| VFD Capacity | 30kW | 45kW | ||

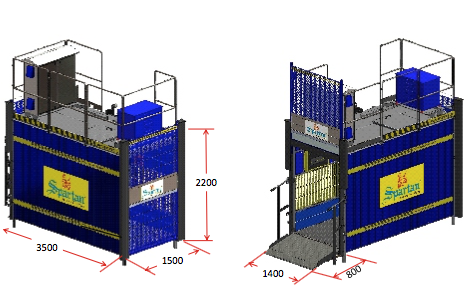

| Cage size LxWxH) | 3.5 x 1.5 x 2.2 mtr. | ||

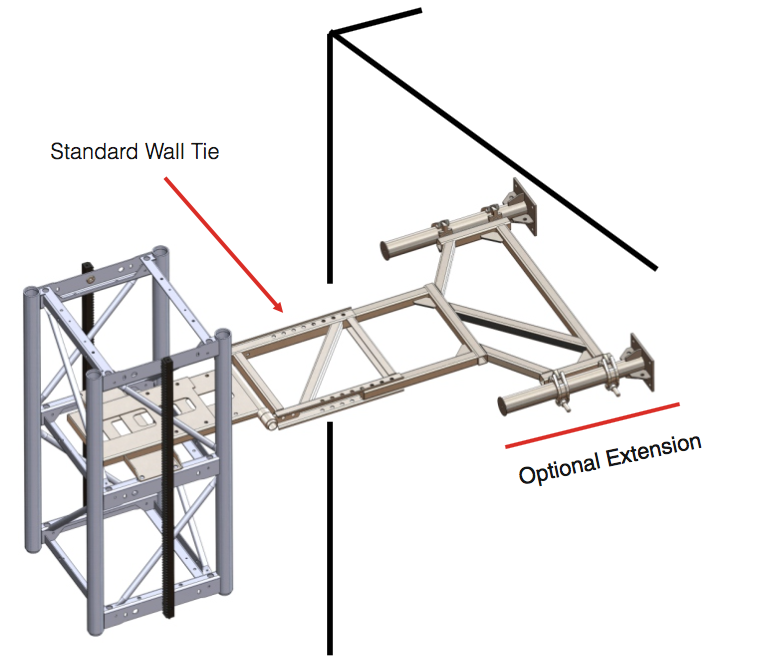

| Wall Tie Interval | 6 mtr. - External Installation | ||

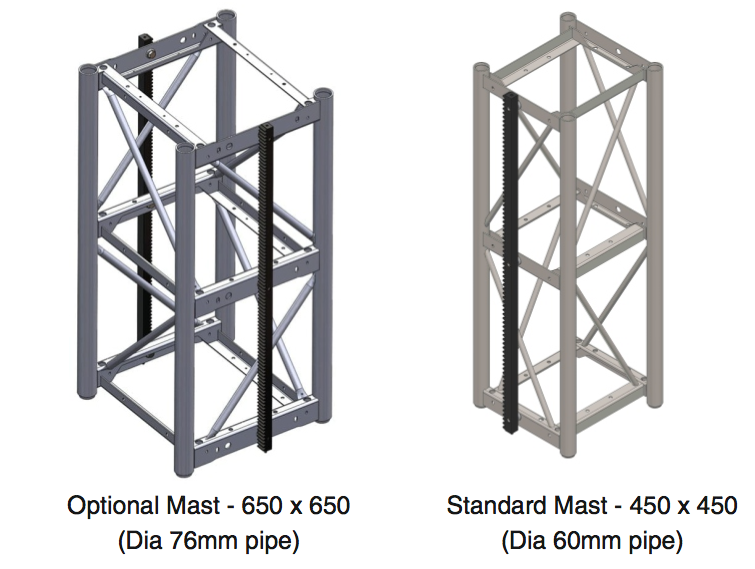

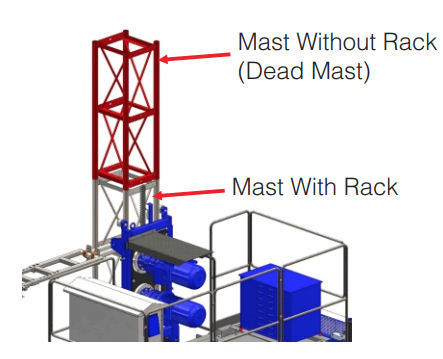

| Mast | |||

| Size (center to center) | Square Tube - 450 x 450 x 1508 | ||

| Section | Round Tube Dia 60 x 4.5 Thickness | ||

| Optional Mast | Square Tube - 650 X 650 x 1508(Round Tube Dia 76.6 x 4.5 Thikness) | ||

| Rack Module | 6 | ||

| Foundation Size (L x W x Thk.) (mtr) | 4.42 x 4.27 x 0.3 Thk. | ||

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

WhatsApp us