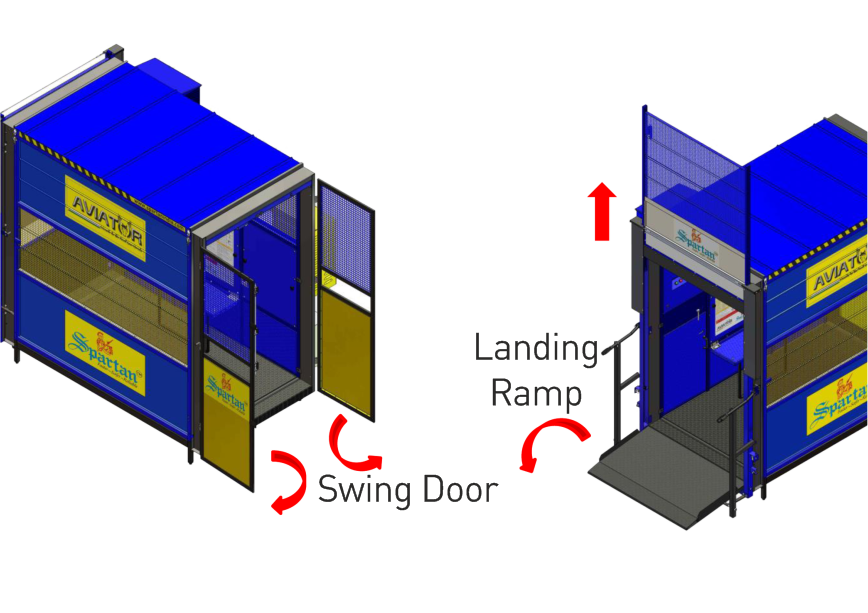

| Model | SPM 200-200L LS | SPM 200-200L HS | |

|---|---|---|---|

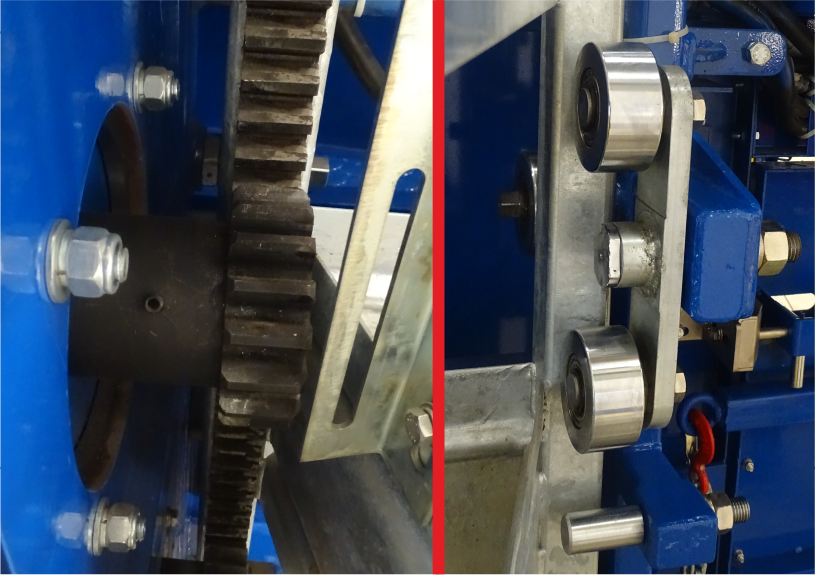

| Drive Mechanism | Rack and Pinion | Rack and Pinion | |

| Capacity | 2.0 Ton (Per Cage) | 2.0 Ton (Per Cage) | |

| Max Height | 250 mtrs. | 250 mtrs. | |

| Speed | 30 mtrs./ min | 54 mtrs./ min. | |

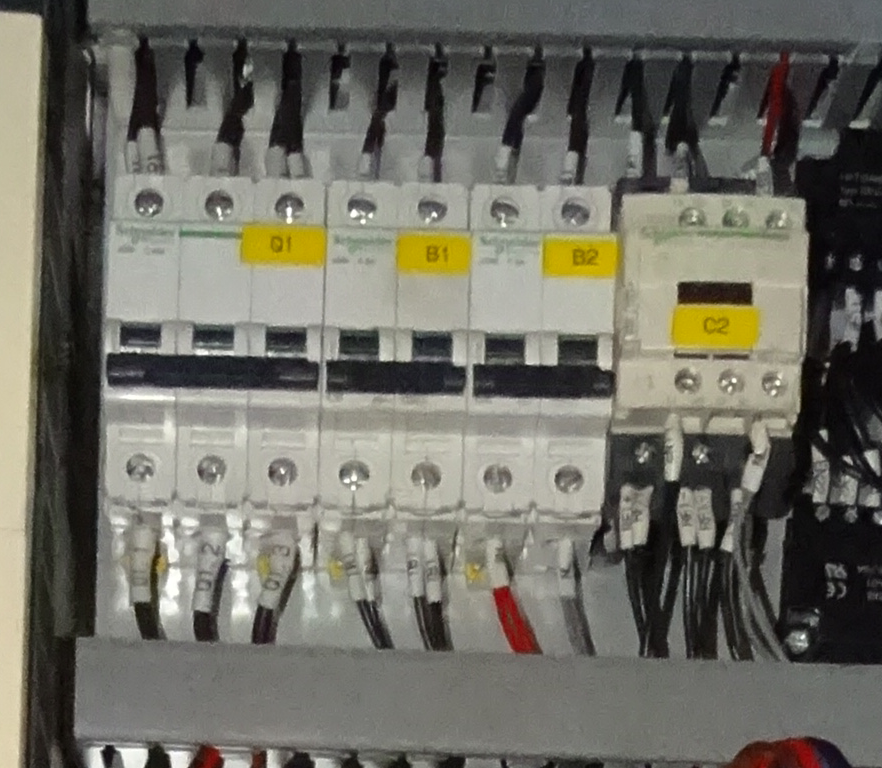

| Motor Power | 14.36 kW (87Hz) x 2 Nos. (Per Cage) | 19.03 kW (87Hz) x 2 Nos. (Per Cage) | |

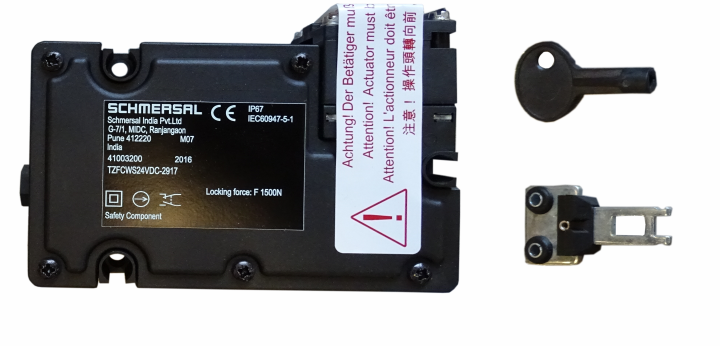

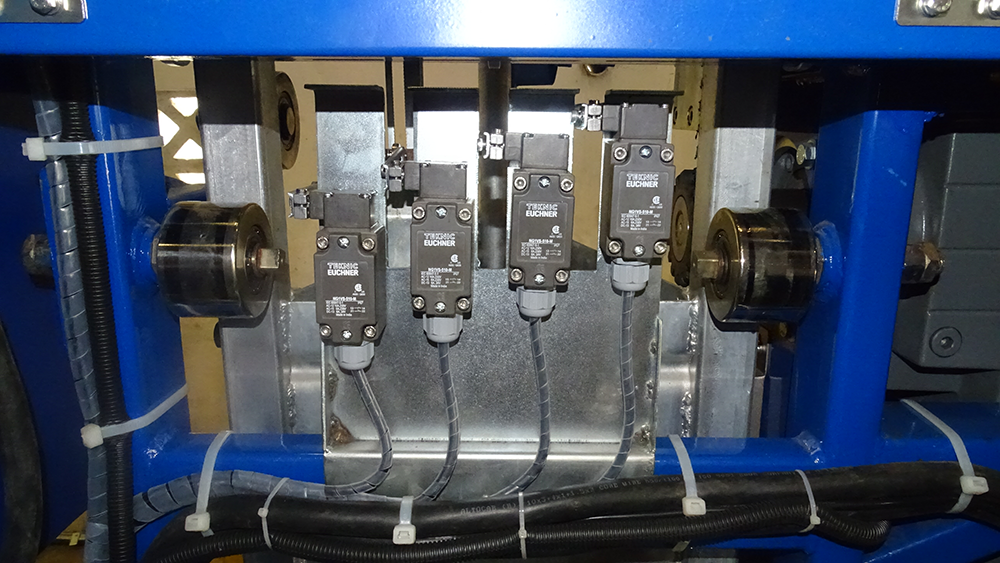

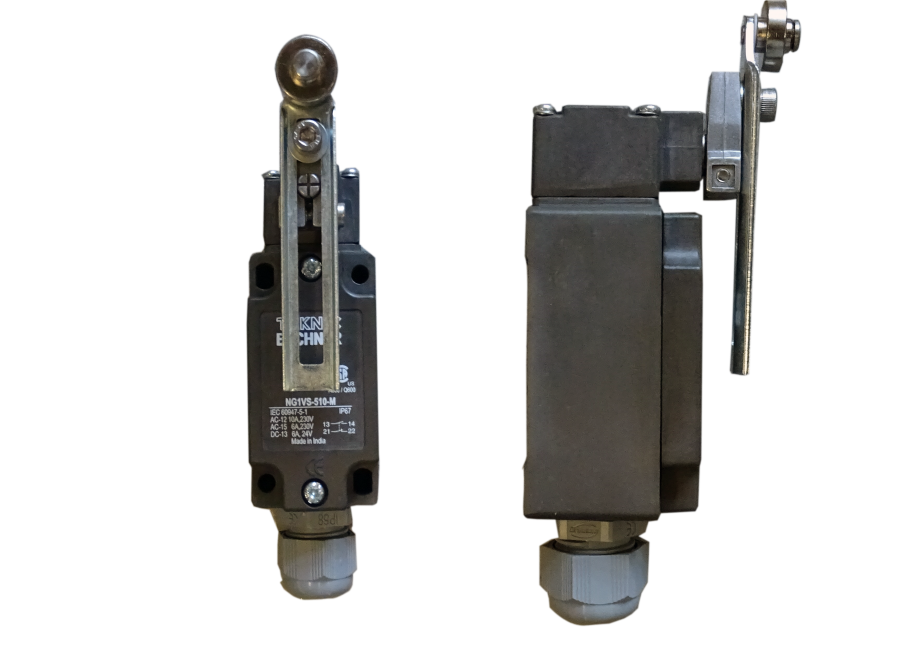

| Safety Device | SSD 3500 | SSD 3500 | |

| VFD Capacity | 30 kW (Per Cage) | 45 kW per Cage | |

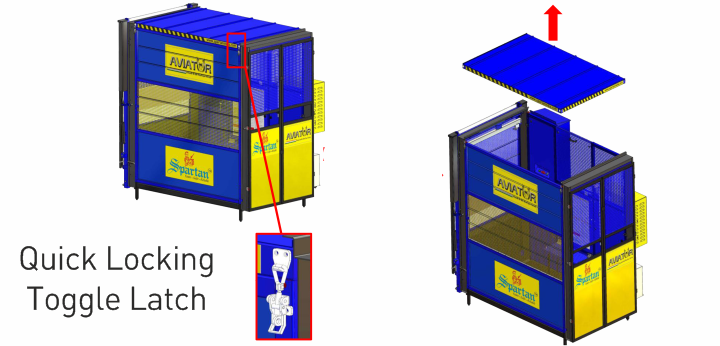

| Cage size LxWxH) | 3.0 x 1.4 x 2.3 mtr. | 3.0 x 1.4 x 2.3 mtr. | |

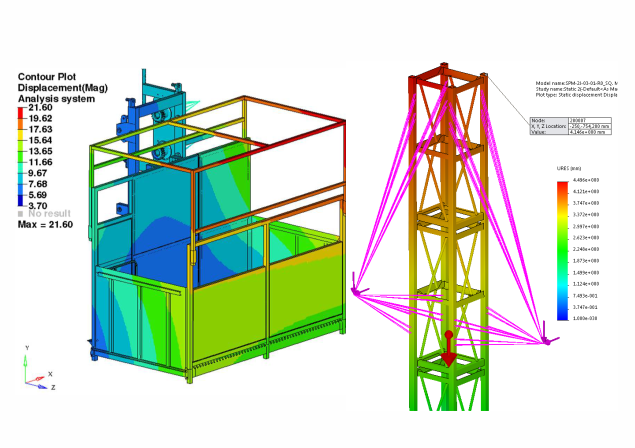

| Wall Tie Interval | 6 mtr. - External Installation | 6 mtr. - External Installation | |

| Mast | |||

| Size (center to center) | Square - 500 x 500 x 1508 | Square - 500 x 500 x 1508 | |

| Section | For 150 mtr. - Sq. Tube 60 x 60 x 4 Thk. For 250 mtr. - Sq. Tube 60 x 60 x 6 Thk. - Till 60 mtr. Sq. Tube 60 x 60 x 4 Thk. - From 60 mtr. to 250 mtr. |

For 150 mtr. - Sq. Tube 60 x 60 x 4 Thk. For 250 mtr. - Sq. Tube 60 x 60 x 6 Thk. - Till 60 mtr. Sq. Tube 60 x 60 x 4 Thk. - From 60 mtr. to 250 mtr. |

|

| Rack Module | 6 | 6 | |

| Foundation Size (L x W x Thk.) (mtr) | 4.05 x 5.30 x 0.3 Thk. | 4.05 x 5.30 x 0.3 Thk. | |

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

WhatsApp us