* Except SPM 100 L & SMH 100l

* Except SPM 100L & all SMH Models

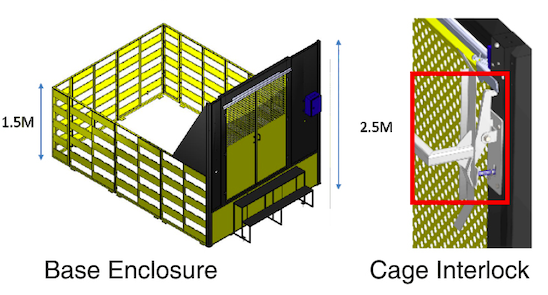

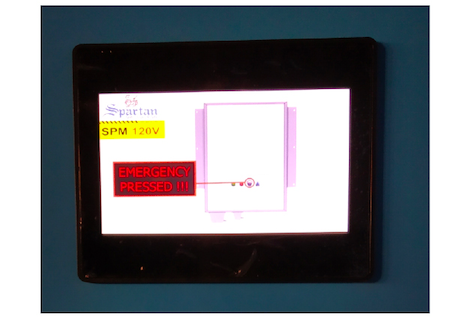

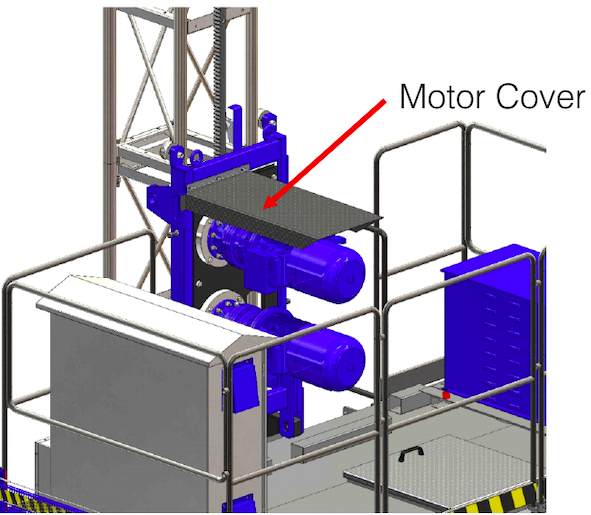

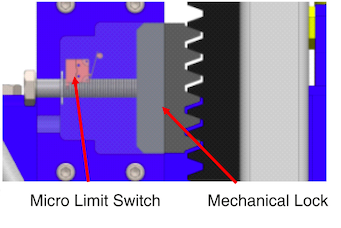

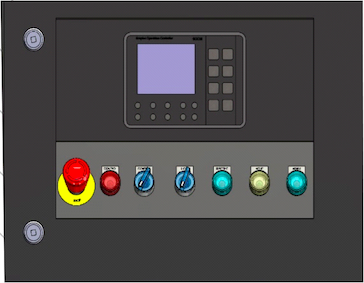

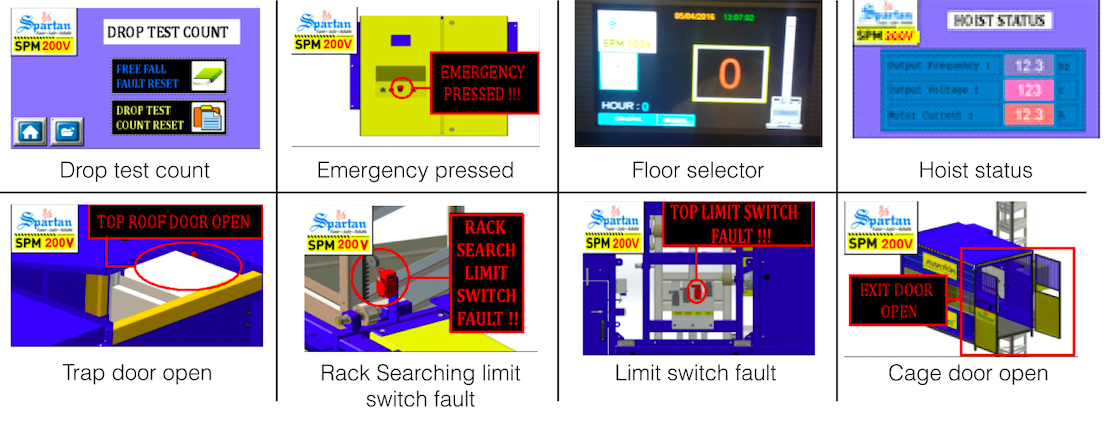

Bottom Limit | Top limit | Entry Door | Exit Door | Final Limit | Rack Searching | Slow Down Limit Service Platform | Base Enclosure Gate | Micro limit switch for safety device Mechanical lock for machine | Mechanical lock for cage door | Trap Door

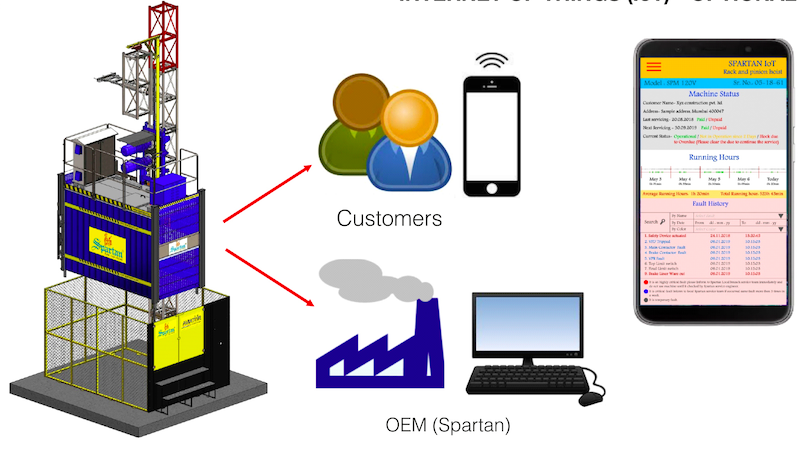

CUSTOMER ACCESS FOLLOWING DATA OF MACHINE

OEM WITH FOLLOWING INFORMATION

| Model | SPM 200L | |

|---|---|---|

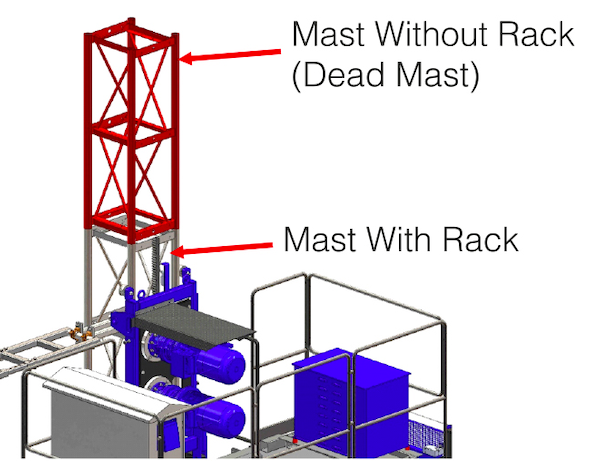

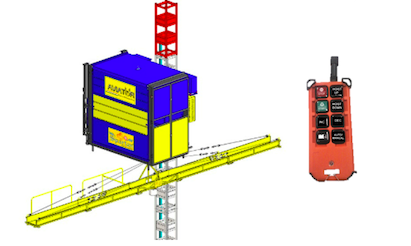

| Drive Mechanism | Rack & Pinion | |

| Capacity | 2.0 Ton | |

| Max Height | 150 mtrs. | |

| Speed | 30 mtr/ min. | |

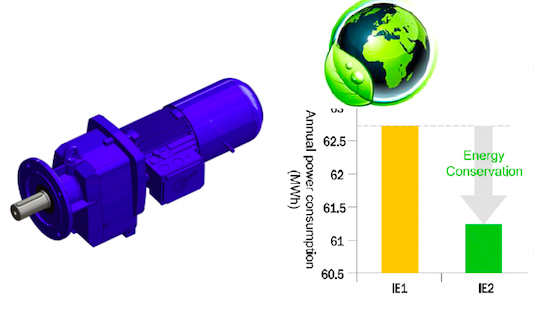

| Motor Power | 9.57 kW (87Hz) x 2 Nos. | |

| Safety Device | SSD 3500 | |

| VFD Capacity | 30kW | |

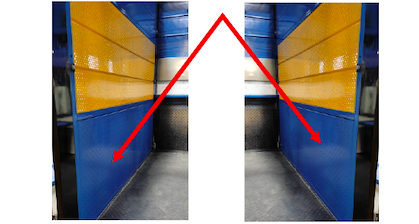

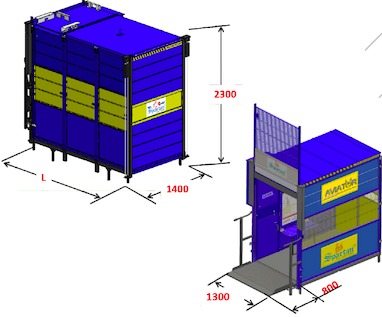

| Cage size LxWxH) | 3.0 x 1.4 x 2.3 mtr. | |

| Wall Tie Interval | 6 mtr. - External Installation 3 mtr. - Lift Shaft Installation |

|

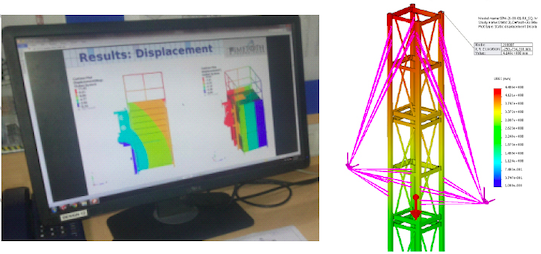

| Mast | ||

| Size (center to center) | Square - 400 x 400 x 1508 | |

| Section | Front - Sq. Tube 50 x 50 x 4 Thk. | |

| Rack Module | 6 | |

| Foundation Size (L x W x Thk.) (mtr) | 3.67 x 3.33 x 0.3 Thk. | |

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

WhatsApp us