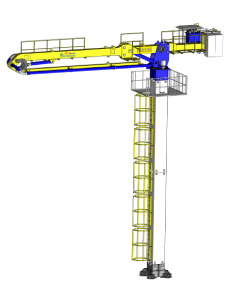

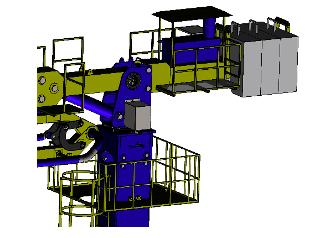

Boom make is high quality & strength material of Strenx 600

Safety Platform is provided for additional safety during maintaince & assembly

Slewing mechanism with Slew ring Made of high strength material is provided for long service life.

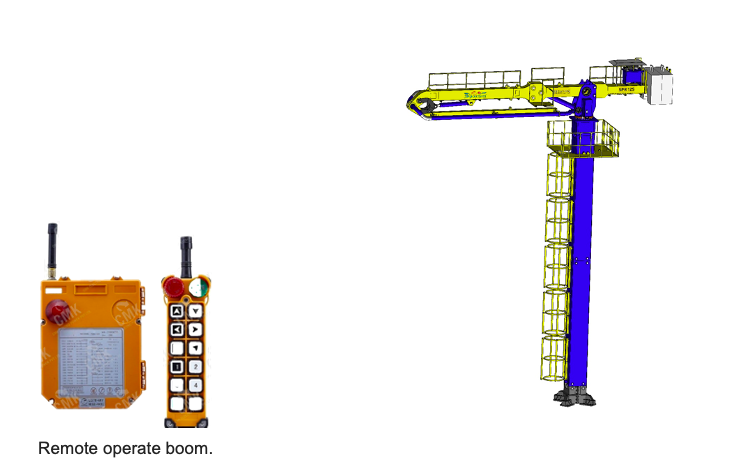

Wireless remote control having 100 mtr range is provided for easy convenient and safe operation

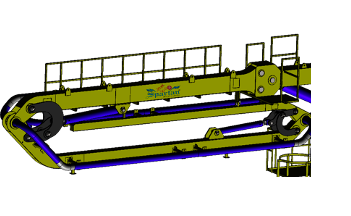

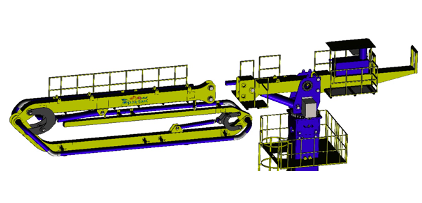

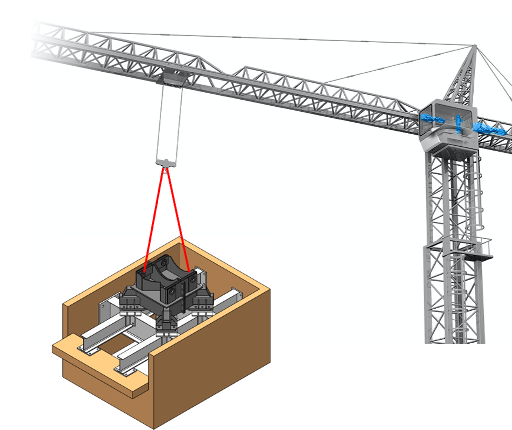

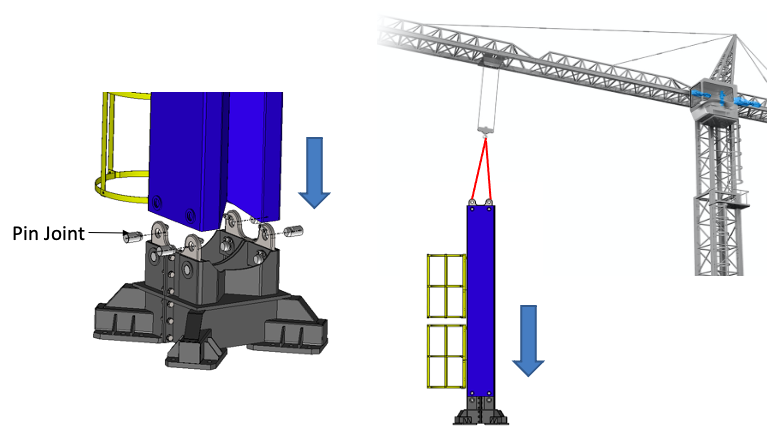

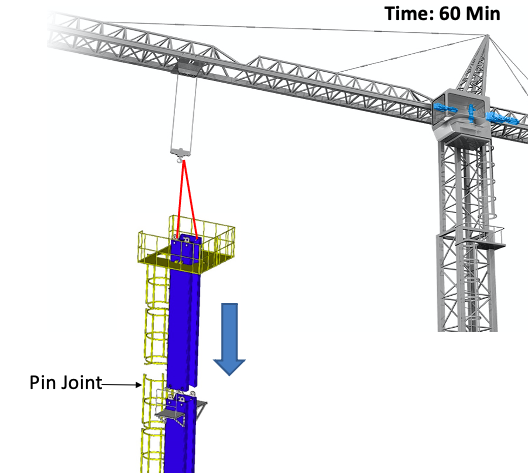

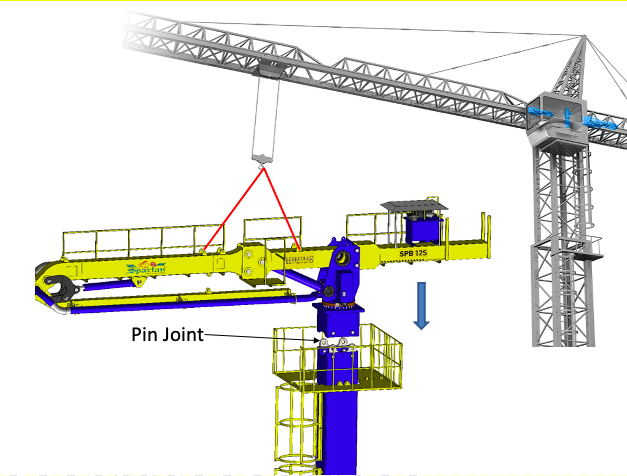

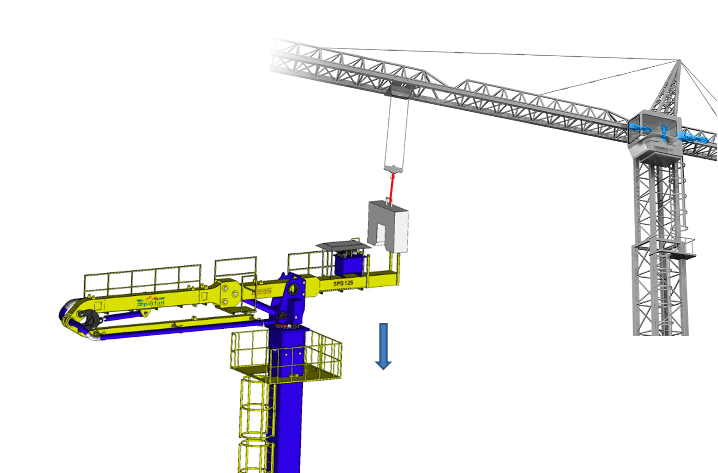

Detachable Boom Design Distributes weight in multiple modules resulting in reduced module weight for easy & faster erection, dismantling through low capacity tower crane.

Reliable and heavy duty snap coupling at pipe joints makes pipe dismantling and assembly easy without any need of spanner or any special tool.

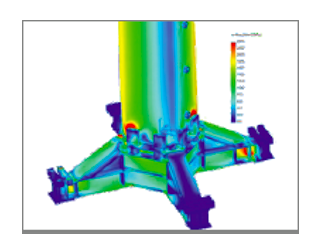

Entire Structure of machine has been designed on basis of FEA study by considering various loading conditions to ensure the life, reliability and safety.

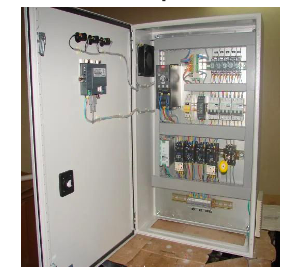

CE standard control panel confirms sustain ability of electrical panel & its component as per international standard which results in zero breakdown

Concrete counterweight with 1 Ton weight.

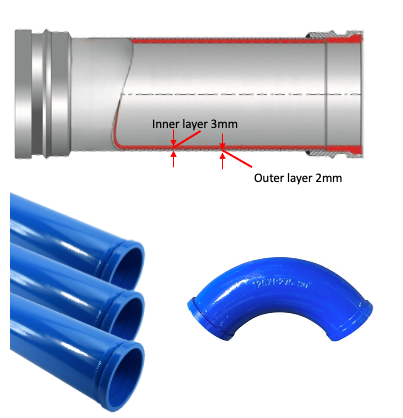

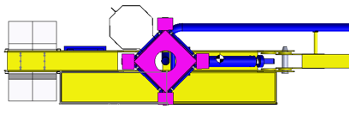

Material: SEAMLESS ST52

PIPE THICKNESS: 5 MM

The Double layer pipes & bends used in boom. It has high performance & 3 time life than single layer pipe

PARKAR make Flexible rubber hose pipe

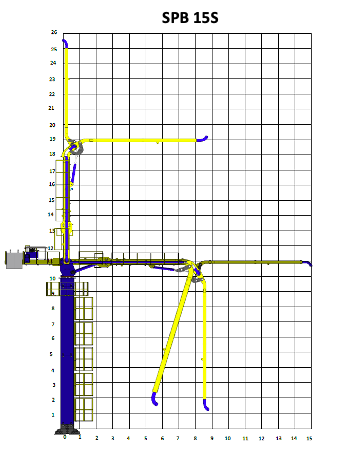

Total weight of SPB 15S = 8800 kg.

(WITH COUNTER WEIGHT)

Consider Pump jerk factor 1.3 Total load= 11440 Kg.

Load at Point A = 30000 kg

Load at Point B = 2500 kg

Load at Point C = 30000 kg

Load at Point D = 1500 kg

TURNING MOMENT AT ‘C’ = 300 KN-Mtr

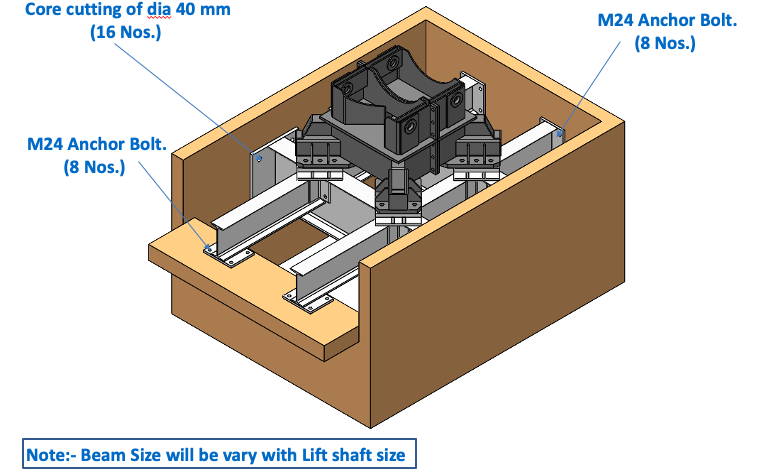

Install I beam frame in lift shaft with anchoring & then mount base frame on I beam frame with M30 Bolts

Add 2 Nos counterweight (1 Ton Each) one by One on counterweight Boom as shown in fig.

| Make | Spartan | |

| Max. Radius of Placing Boom | 15 meter | |

| Arms | 2 arms / Roll and Fold | |

| Free Standing Height | 9.5 mtr. | |

| Maximum radious achievable | 15 mtr. | |

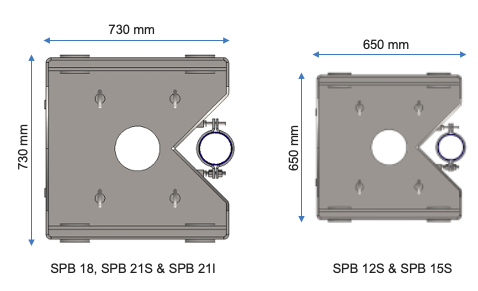

| Mast Set Options(outer) | (650 x 650 x 4.5 mtr) | |

| Mast Type/Qty. | ‘M’ TYPE SOLID PLATE x 2 Nos. | |

| Centre Slewing Range (°) | 360. | |

| Total weight (kgs.) (without counter weight) | 6800kgs. | |

| Heaviest Single Piece | 2000 kg. | |

| Counter Weight | 1000 kg x 2 Nos. | |

| Control Systems | Auto (motorised) | |

| Pipeline Diameter | 125 mm. | |

| Boom 1st Section | Length Articulation |

7.8 mtr. 0 to 90 deg |

| Boom 2nd Section | Length Articulation |

7.2 mtr. 0 to 180 deg |

| Slab core cutting size | 900 mm x 900 mm | |

| Electric Power | 400 V/50 Hz | |

| Working Range Dia | 30 meters | |

| End Hose For concreting | Dia 125 mm / 3 m length | |

| Hydraulic system motor | 5 hp | |

| Hydraulic System working Pressure | 250 bar | |

| Oil Flow | 6 LPM | |

| Power Pack Tank Capacity | 85 Ltrs | |

| Climbing Type | Tower Crane | |

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

Error: Contact form not found.

WhatsApp us