As you are aware, it means any improvement, one-time or continuous, large or small. Kaizen is a daily process, the purpose of which goes beyond simple productivity improvement. Spartan’s aim is towards a process that, when done correctly, humanizes the workplace, eliminates overly hard work and perform experiments on their work using the scientific method and learn to spot and eliminate waste in business processes. In all, the process suggesting a humanized approach to workers, thus increasing productivity. Spartan envisions the participation of workers in the improvement, people at all levels of the organization participate in kaizen, from the CEO down to janitorial staff, as well as external stakeholders when applicable. It is an on going and consistent process followed at Spartan, with proper implementation and review mechanisms.

Spartan aims to built a work space for efficiency and effectiveness by identifying and storing the items used, maintaining the area and items, and sustaining the new order.

We achieve the above by following the below steps:

Sorting is done through all items in a location and removing all unnecessary items from the location.

Goals:

Implementation Procedure:

To standardize the processes used to sort, order and clean the workplace.

Goal:

Implementation Procedure:

Setting in order is putting all necessary items in the optimal place for fulfilling their function in the workplace.

Goal:

Implementation Procedure:

Sustain the developed processes by self-discipline of the workers. Also translates as “do without being told”. Frequent Training sessions are conducted for workers, staff and customers too on 5S and benefits of the same. Fire Fighting Training too was conducted by professionals for workers and staff.

Goal:

Implementation Procedure:

To shine is to sweep or clean and inspect the workplace, tools and machinery on a regular basis.

Goals:

Implementation Procedure:

Spartan follows ZED approach, so that the product is immediately accepted globally ensuring Zero Defect. Spartan has 4 Step ZED Rating Process:

Meetings, where each of HOD from various departments like design, production, marketing, customer care, etc. come together to discuss on various successful machines across the globe. Our design team participates exhibitions across India & globe to study the industry and machineries. This helps us to narrow down on a particular machinery which is appropriate to Indian site conditions. These machines are discussed and finalized during NPD meetings and sent to design team for further development.

Once this design is ready it is shared with production team to prepare a proto type. Once this proto type is manufactured, it is tested in house and also at site to ensure smooth operations at all possible and critical conditions. After certain modifications and successful running of the equipment it is sent to production for mass manufacturing.

Spartans every product goes through stringent quality processes. This ensures that every customer receiving Spartan’s machines are of the best quality and for longer life. Spartan boasts of the following certifications:

QMS ISO 9001: 2015

Safety OHSAS 18001: 2007

Environmental Certificate ISO 14001: 2015

Wind Mill Service Lift CE certificate

Hoist Safety Device CE certificate

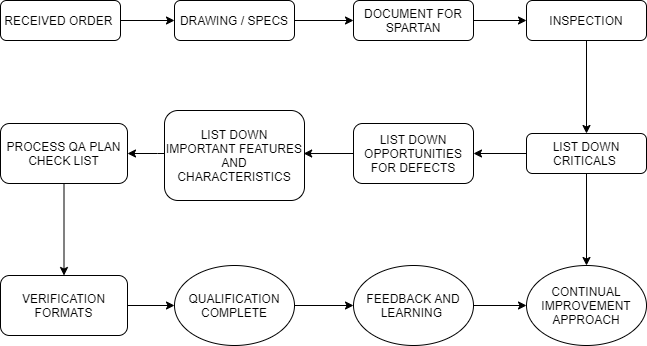

Spartan goes through various levels of quality testing, which ensures a better product, Spartan calls it Quality Roadmap:

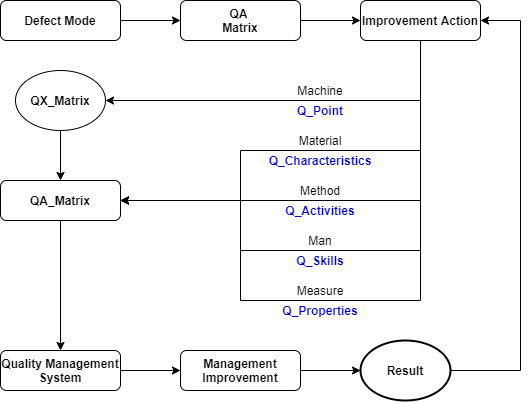

Spartan maintains ‘Quality Maintenance System for Zero Defect’ system for longer life of the machines.

Error: Contact form not found.

WhatsApp us