Key features of puzzle parking sytem

Material

IS2062:E350 (A/BR/BO/C) Grade materials used.

Diamond Make Chain & Sprocket

Chain used for horizontal movement contains a case-hardened pin and heavier sidebars for increased fatigue strength and wear life inhigh speed or abrasive applications.

Electrical Panel & Wire

All switchgear used electrical control panel design as per IEC 61439 standard. All cables & wires are of standard make.

Branded Skf/fag Heavy Duty Bearings

Reliable branded bearing with shock resistance, steady Its life is longer than local make. Improves performance and is breakdown free operation.

Usha Martin Wire Rope used for Lifting Pallet

Excellent resistance to fatigue, wear and abrasion, confirmed by laboratory testing and field experience. A few key factors for preferring the Usha Martin brand are Accident-free performance ensuring maximum human safety & has longer service life.

All Motors

Front wheel stopper arrangement on platform for proper positioning of car.

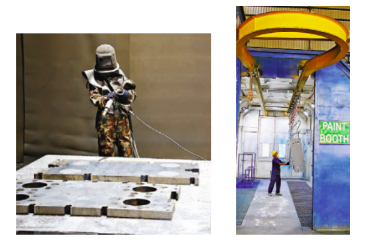

Material Finish

Painting forms a layer of protection that prevents corrosion. It may not be that thick, but it is a dependable layer that prevents outside chemicals from interacting with the steel. Therefore, it ensures your metal projects are more durable in the long run.

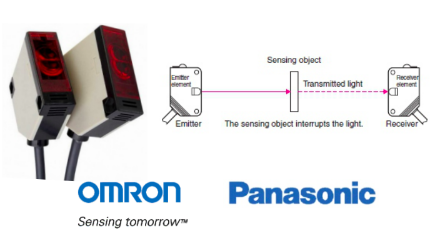

Laser Sensor

Laser sensors used front and rear of the system to detect car positioning and avoid accidents.

Touch Screen Display

Touch screen HMI is provided to select the proper car, number shown on display. All fault indication will be shown on display.

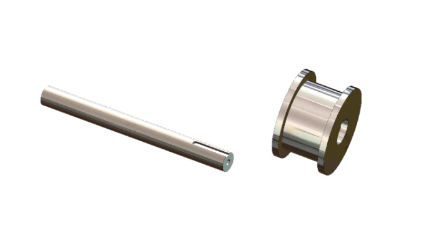

All Roller & Shaft

Hard Crome Plating is versatile and offers many advantages. It is used to keep parts protected from natural wear, abrasion and corrosion, and adds hardness to the surface for all types of applications in varying conditions.

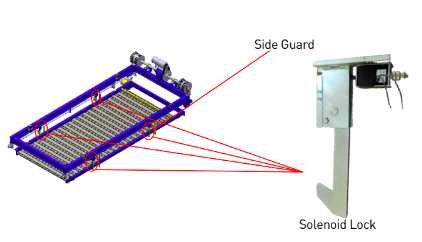

Pallet with Safety Lock

4 nos Solenoid Lock for each pallet to avoid free falling of pallet with car.

Top guard-to avoid car damages in any accident.

Side guard-to avoid to swing pallet during car parked position.

Safety Limit Switch

Limit switch provided in Spartan Stacker is of world wide acclaimed companies like Schmersal , Teknic etc. Branded limit switches give more life, easy for operation and are very reliable.

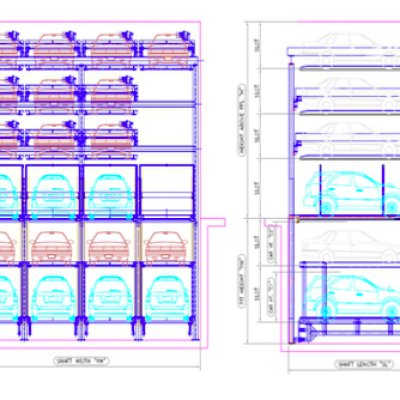

| SHAFT WIDTH (RW) | ||||||||

|---|---|---|---|---|---|---|---|---|

| NO. OF GRIDS | 2 (GRIDS) | 3 (GRIDS) | 4 (GRIDS) | 5 (GRIDS) | 6 (GRIDS) | 7 (GRIDS) | 8 (GRIDS) | 9 (GRIDS) |

| REQ. WIDTH | 5200 | 7600 | 10000 | 12400 | 14800 | 17200 | 19600 | 22000 |

| PIT car details | ||

|---|---|---|

| PIT Height 'PH' | Car Height 'C1’ | Car Height 'C2’ |

| 4500 | 1600 | 1600 |

| 4800 | 1750 | 1750 |

| 5300 | 2000 | 2000 |

| 4650 | 1600 | 1750 |

| 4900 | 1600 | 2000 |

| 5050 | 1750 | 2000 |

| EM Puzzle Parking Technical Specification | |

|---|---|

| SPEED | 2.5 Meters / Minute vertical & 6 Meters / Minute horizontal |

| CAPACITY | 2000 Kgs ( 2500 Kgs Optional) |

| OPERATION | HMI with touch screen display |

| POWER SUPPLY | 415 V, 3 phase, 50 Hz |

| Car Type | Height |

|---|---|

| SEDAN CARS | 1500-1600 |

| HATCHBACK CARS | 1601-1700 |

| TALLBOY CARS | 1701-1850 |

| SUV CARS | 1851-2000 |

| Car | Car Height | Slot |

|---|---|---|

| SEDAN | 1600 | 1850 |

| TALL BOY | 1750 | 2000 |

| SUV | 2000 | 2250 |

| Legend | |

|---|---|

| "H” | HEIGHT |

| "SL” | SYSTEM LENGTH |

| "RW” | SHAFT WIDTH |

| "PH” | PIT HEIGHT |

| "GF” | GROUND FLOOR |

| "C1” | CAR HEIGHT |

| "C2” | CAR HEIGHT |

| "KG” | KILOGRAM |

As per available space at site, pallet width & car width can be decreased or increased with the multiple

Pit car width = car width above ground – 100mm

| Total Levels | Height (H) | Length For 5000mm Car Length (Sl) | |

|---|---|---|---|

| ALL SUV | 2 | 4500 | 6200 |

| 3 | 6750 | 6200 | |

| 4 | 9000 | 6200 | |

| 5 | 11250 | 6200 | |

| 6 | 13500 | 6200 | |

| 7 | 15750 | 6500 | |

| 8 | 18000 | 6500 | |

| APPROX. 50% SUV | 2 (1LVL. SUV) | 4100 | 6200 |

| 3 (2 LVL. SUV) | 6350 | 6200 | |

| 4 (2 LVL. SUV) | 8200 | 6200 | |

| 5 (3 LVL. SUV) | 10450 | 6200 | |

| 6 (3 LVL. SUV) | 12300 | 6200 | |

| 7 (4 LVL. SUV) | 14550 | 6500 | |

| 8 (4 LVL. SUV) | 16400 | 6500 | |

| ALL SEDAN EXCEPT GF LVL. | 2 | 4100 | 6200 |

| 3 | 5950 | 6200 | |

| 4 | 7800 | 6200 | |

| 5 | 9650 | 6200 | |

| 6 | 11500 | 6200 | |

| 7 | 13350 | 6500 | |

| 8 | 15200 | 6500 |

No. Of grids x 2400 + 400 will be the required total width For 2000mm pallet width & 1900mm car width

Car Length = System Length (Sl) – 1200mm